At Apparent Technologies, our mission is to be a pioneering force in the manufacturing industry, dedicated to delivering exceptional quality, innovation, and value to our customers.

We are committed to fostering a culture of precision and excellence, leveraging cutting-edge technologies and sustainable practices to create products that meet and exceed the evolving needs of our global clientele. Through a relentless pursuit of operational excellence and a focus on customer satisfaction, we aim to be the preferred partner for manufacturing solutions, driving growth, and creating lasting value for our stakeholders, employees, and the communities we serve.

Our Services

-

Engineering

SolidWorks

Mastercam

MBD Integrated

-

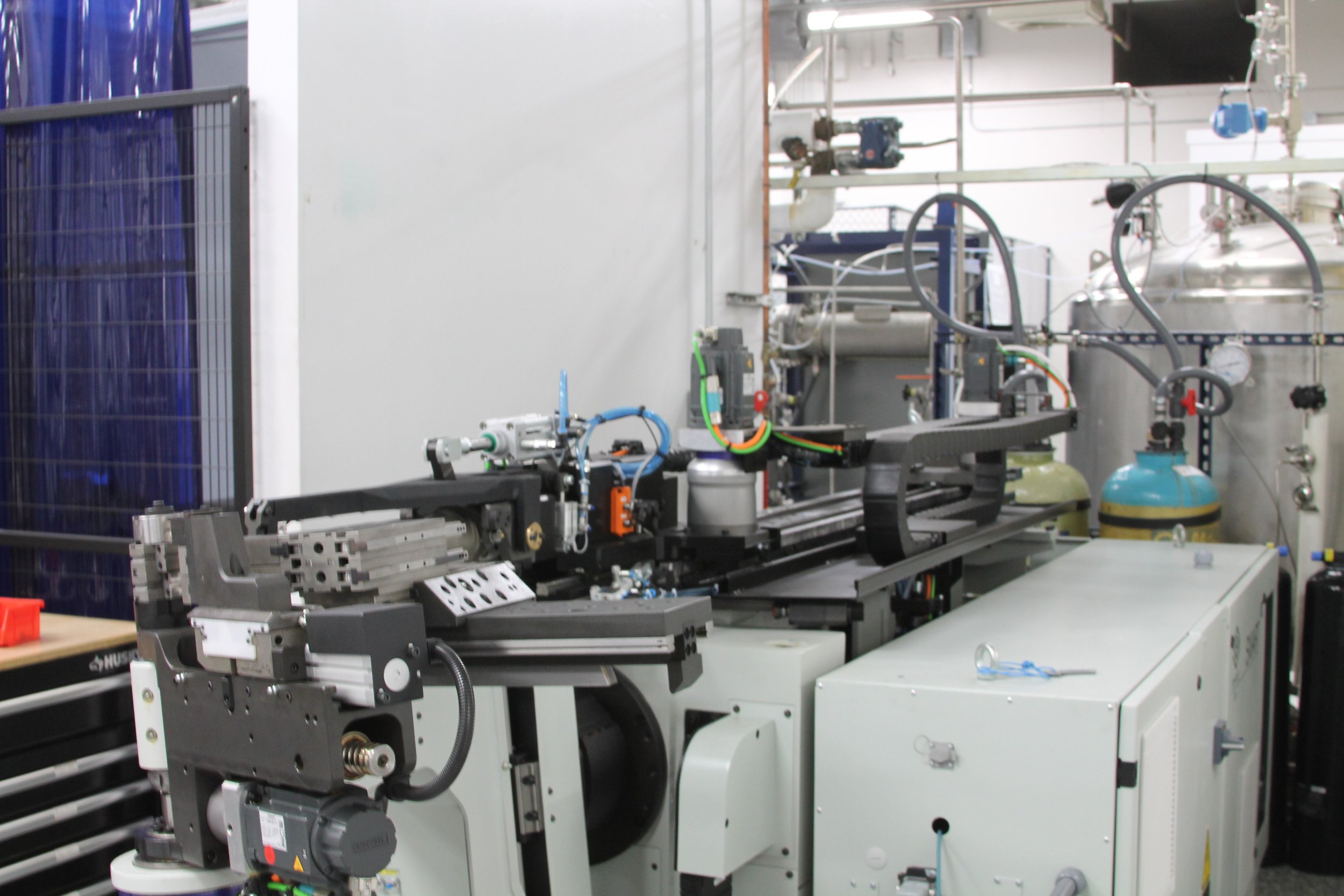

Orbital Welding

Proprietary, in-house manufactured,

orbital welding system and processISO 5 Cleanroom

-

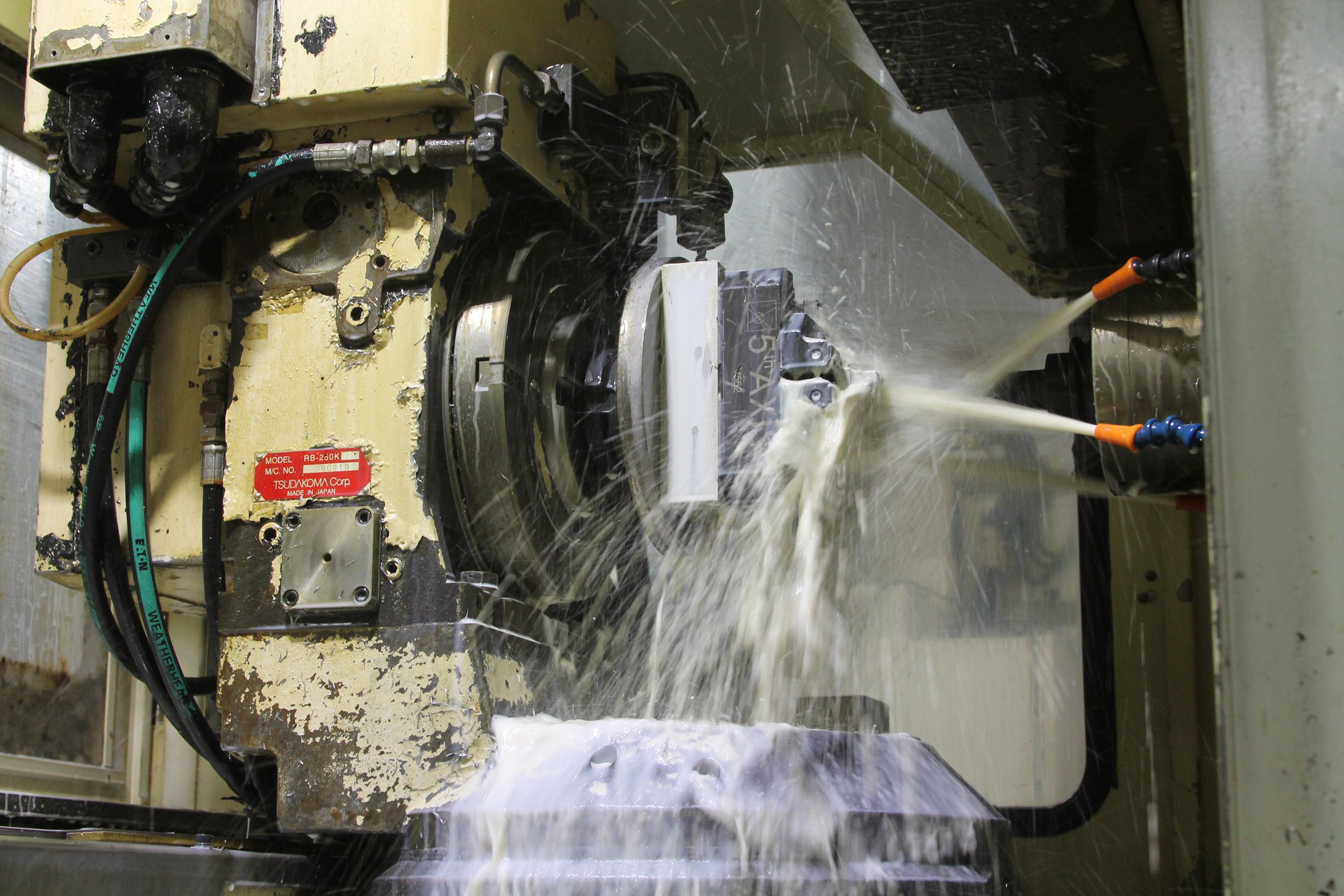

CNC Machining

3, 4 and 5 Axis machining centers

CNC Lathe

-

TIG Hand Welding

¼” to 4” Diameter Capable

-

Component Finishing

Mechanical Polishing

Extrude Honing

Electropolishing

-

Inspection & Testing

Helium leak testing

Particle testing

MBD integrated CMM inspection

-

High Purity Cleaning

Heated and Cooled Type 1 D.I. Water System

Large Volume Ultrasonic Capability

-

Tube Processing & Bending

High capacity (ECG) Cutoff Machine

CNC Tube Bender capable of up to 1” Diameter

Our Technology

Our technology stands out as the best due to our cutting-edge innovation, efficiency, and reliability. With a focus on precision and automation, our technology streamlines production processes, resulting in higher productivity and reduced operational costs. The integration of advanced materials and state-of-the-art machinery ensures a superior quality output, meeting and exceeding industry standards.

In addition, our commitment to sustainability through energy-efficient practices positions your manufacturing technology as not only a leader in performance but also in environmental responsibility.

Orbital Weld Heads

Patented, proprietary design manufactured and maintained In house

Unique features to Increase productivity:

- Foot petal operated

- Automatic clamping

- Compact design for weld configuration versatility

- Alignment accuracy to reduce tacking requirements and maintain

weld integrity

Reduced cycle times, power requirements, and heat production

Power Supplies

Automated purge control and oxygen sensing

High resolution, Autonomous weld Data collection including

but not limited to:

- Oxygen Levels

- Amperage

- Voltage

- Travel Speed

Early detection of equipment failures through data analysis

Versatility that allows for tacking or orbital welding at each station

Contact us for a FREE quote.

Contact us for a free quote and experience the unparalleled combination of cutting-edge technology, precision engineering, and cost-effective solutions tailored to meet your specific needs, ensuring optimal results for your production requirements.